VSSI has just been awarded a 3 year contract by APPLUS VELOSi in Oman for the provision of Hybrid Acoustic Technology System (HATs) services for the inspection of Static Assets to establish Fitness for Service (FFS) to be performed for Occidental Oman Mukhaizna assets.

VSSI has carried out several inspections for Oman Refinery and Petrochemical Industries Company in Oman and, with our Sister concern MRA, is carrying out inspections extensively for Petronas Carigali, Saudi Arabia SABIC among others.

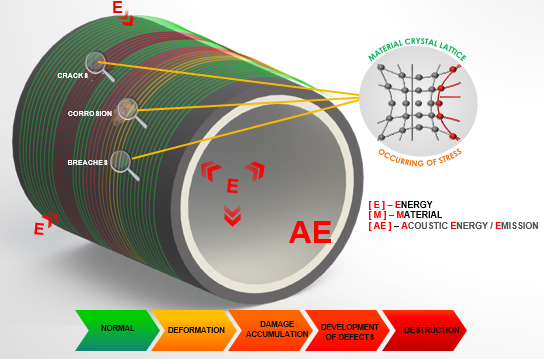

The Technology is based on Non Intrusive Hybrid Acoustics and thus best suited to assets that are in the operational phase. HATS provides the Size, Severity, Number and classifies the anomalies according to the mechanism of the anomaly eg. corrosion, metal loss, cracks etc..

HATS can cover a distance of upto 2 kilometers of continuous pipe inspection without the need for intermediate excavation or multiple inspections along the length of the pipe.

HATs is not limited by the size, thickness or orientation of the pipe HATs is only limited to metallic assets only.

☼HATs allow screening or diagnostic of metallic objects.

☼HATs reduce the volume and labour intensity of monitoring, repair and tests

☼HATs simplify the preparation of Standards and Procedures for maintenance program.

☼HATs is cost effective in the context of total plant inspection, maintenance and repair cost.

☼HATs monitoring/data gathering can be conducted without plant shutdown or production interruption.

☼HATs is operable on wide temperature range (-50oC to 280oC -even higher depending on wave guide capability).

☼HATs provides real time data acquisition which can be utilized for assessment up to Fitness for Service (FFS).

☼HATs requires minimal modification to the diagnosed candidate and operation parameters are maintained during monitoring/data gathering.

☼HATs is not affected by variable diameter, fittings and flanges, limited accessibility and can be applied in most climatic conditions.